LIQUID LEVEL MEASUREMENT

POSITION

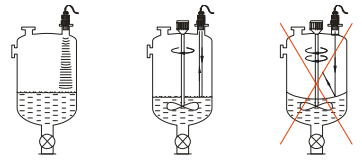

The ideal position of the EasyTREK is on the radius r = (0.3 – 0.5) R of the (cylindrical) tank / silo. (Take also sonic cone on page 5 into consideration.)

SENSOR ALIGNMENT

The sensor face has to be parallel to the surface of the liquid within ±2° – 3°.

TEMPERATURE

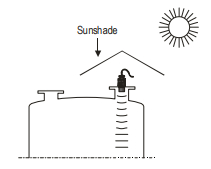

Make sure that the transmitter is protected against overheating by direct sunshine.

OBSTACLES

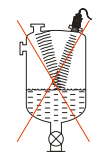

Make sure that no objects (cooling pipes, bracing members, thermometers etc.) protrude into the sensing cone of the ultrasonic beam.

Remark: EasyTREK programming allows one fixed object that would otherwise disturb the measurement to be blocked out. (see P29 of programming).

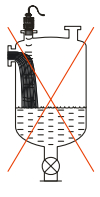

FOAM

Foaming of the liquid surface may render ultrasonic level metering impossible. If possible, a location should be found, where foaming is the least (device should be located as far as possible from liquid inflow) or a stilling pipe or well should be used.

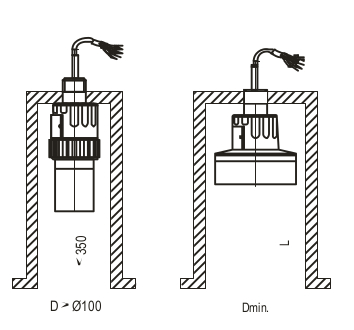

STAND-OFF

WIND

Intensive air (gas) movements in the vicinity of the ultrasonic cone is to be avoided. A strong draft of wind may "blow away" the ultrasound. Devices with lower measuring frequency (40, 20 kHz) are recommended.

FUMES / VAPOURS

For closed tanks containing chemicals or other liquids, which creates fume/gases above the liquid surface especially for outdoor tanks exposed to the sun, a strong reduction of the nominal measuring range of the ultrasonic device is to be considered during device selection. Devices with lower measuring frequency (40, 20 kHz) are recommended in these cases.

The structure of the stand off pipe should be rigid; the inner rim where the ultrasonic beam leaves the pipe should be rounded.

| L | Dmin | ||

| SP-59 | SP-58 | SP-57 | |

| 150 | 50 | 60 | 60 |

| 200 | 50 | 60 | 75 |

| 250 | 65 | 65 | 90 |

| 300 | 80 | 75 | 105 |

| 350 | 95 | 80 | 120 |

| L | Dmin |

| SP-54 | |

| 90 | 130 |

| 200 | 140 |

| 350 | 150 |

| 500 | 160 |

OPEN CHANNEL FLOW MEASUREMENT

- The unit is suitable for open channel flow measurement with the constructive works listed in 5.3.8.

- For ultimate accuracy, install the sensor as close as possible above the expected maximum water level (see minimum measuring range).

- Install the unit in a place defined by the characteristics of the metering channel along the longitudinal axis of the flume or weir. In case of Parshall flumes supplied by NIVELCO the location of the sensor is marked.

- In some cases foam may develop on the surface. Make sure that the surface, opposite to the sensor, remains free of foam for proper sound reflection.

- In some cases foam may develop on the surface. Make sure that the surface, opposite to the sensor, remains free of foam for proper sound reflection.

- The unit should be fixed so that it’s position would not change.

- From measurement accuracy point of view the length of the channel sections preceding and following the measuring flume and their method of joining to the measuring channel section are of critical importance.

- Despite of the most careful installation, the accuracy of flow metering will be lower than that of specified for the distance measurement. The features of the flume or weir applied will determine it.

- Devices should be protected against overheating due to direct sunshine by using sunshades.